Indoor AgTech spoke to Neil S. Mattson, CEA Director and Associate Professor, School of Integrative Plant Science, Horticulture at Cornell CALS on the University’s mission for optimizing plant science, unveiling exciting collaborations and the biggest challenges and trends facing indoor agriculture.

You’re speaking at the Indoor AgTech Innovation Summit about Plant Science and Optimizing Traits to Indoor Systems.

What do you see as the most exciting business opportunity/area of technology development in the Indoor AgTech space today? Where do you see the next big breakthrough occurring?

To me the biggest breakthroughs are around bio-feedback; in the past we have sensed the environment the plants are growing in, and used this information to control greenhouses and plant factories. Through our collaboration with RPI’s Lighting Enabled Systems & Applications center we’re now listening to the plants themselves, using sensors to make sense of plant patterns and using this intelligence to make real time decisions about what’s best for them. As an example, plants can tell us when they are stressed from too much light or specific wavebands of light, and this can be used to adjust lights, enhancing plant outcomes and saving energy.

Cornell CEA is working in partnership with GLASE, (Greenhouse Lighting and Systems Engineering) and a National Science Foundation funded project. How are these projects progressing?

The Greenhouse Lighting Systems Engineering consortium has been active for one year now. We have 350 specific milestones, from technical research to developing an industry consortium which would make our research self-sustaining. We started signing up members from April and already have eight members. The project is especially finding a niche with new technology and lighting companies – they may have great computer science and engineering backgrounds, but our own research teams are doing a great job of translating for them what plants actually need, such as helping them understand units, measurements, and quantifying plant response to photosynthetically active radiation.

Our National Science Foundation project has only been running five months, so we’re still fairly early into our work of better understanding and enhancing the viability of urban controlled environment agriculture. A key success story is our student outreach program, which came into being after learning from several CEA enterprises that there were significant barriers finding qualified employees with an understanding of both plant physiology and systems engineering. Four different NYC-based enterprises are hosting Cornell students as a field-based approach to integrating them within the industry.

What do you see as the biggest challenge facing Indoor AgTech companies in achieving market penetration?

A major challenge is that our target markets are already really well-served by traditional agriculture; for example, there is abundant lettuce in the marketplace and supermarket space is full. Indoor Ag needs to mature as an industry, to the extent that they can showcase the benefits to produce buyers, develop a larger critical mass of producers which in turn will drive demand for technology companies to share their latest and greatest solutions. It’s a chicken and egg scenario, we want the new technology to support the industry, but need the industry to grow its demand for new tech.

What new collaborations or trends are you seeing in the industry? What new collaborations are we likely to see in the future?

We’re seeing exciting collaborations where experts in big data – like Microsoft, Intel, Dell and IBM – are now really engaging with ag, and specifically with CEA, for example Dell’s partnership with AeroFarms. These big data companies bring skill sets not previously applied to agriculture, it’s really exciting to see these two fields align.

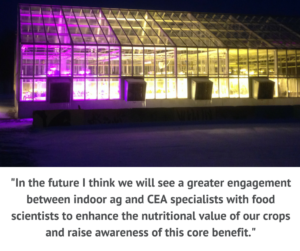

Something we’re not seeing a lot of yet, but I think will see in the future is greater engagement between indoor ag and CEA specialists with food scientists, to hone in on and enhance the nutritional value of our crops and raise awareness of this core benefit. Working with great food scientists that have the analytical equipment and insights into how we can truly differentiate the next generation of indoor grown produce. Perhaps we’ll see the introduction of a standardized produce label that highlights the indoor-grown connection to quantifiable advanced nutritional benefits.

What are your plans for Cornell CEA over the next 12 months and at the Indoor AgTech Summit?

Historically our program has been strong on plant science, engineering and controls, but what excites me about the Indoor AgTech summit is the inter-disciplinary sc ope. Not just with meeting producers but all the inter-related technologies, systems and computer science connecting with all the allied partners that are bringing different solutions to different pieces of the same puzzle. We want to engage with the industry to understand what are the challenges for companies as they advance – such as energy savings, plant science – and we’re keen to meet partners. Our own research will continue in plant responses to lighting, incorporating more computer vision, advanced machine-learning and bio-feedback. We also believe bio-feedback enabling quick results will allow for shorter experiments and really allow us to make progress more quickly.

ope. Not just with meeting producers but all the inter-related technologies, systems and computer science connecting with all the allied partners that are bringing different solutions to different pieces of the same puzzle. We want to engage with the industry to understand what are the challenges for companies as they advance – such as energy savings, plant science – and we’re keen to meet partners. Our own research will continue in plant responses to lighting, incorporating more computer vision, advanced machine-learning and bio-feedback. We also believe bio-feedback enabling quick results will allow for shorter experiments and really allow us to make progress more quickly.

Neil Mattson will join the Plant Science panel on Optimizing Traits to Indoor Systems at 3pm on June 21.

John March, Chair, Biological and Environmental Engineering of Cornell University will deliver a keynote session on Building the Future of Food Through Collaboration at 10am on June 21.

To learn more about Cornell CEA, visit cals.cornell.edu/indooragtech2018 or follow them on Twitter @CornellCALS.

CLOSE

CLOSE